The cost of CNC machining can often seem complex and confusing. This is especially true when comparing the expense of a single piece versus producing multiple parts. Why does creating just one piece often cost much more than producing many of that same part?

Read on for an explanation of what influences CNC machining costs and a better understanding of why single pieces have a sticker shock while multiple pieces do not.

Understanding CNC Machining Costs

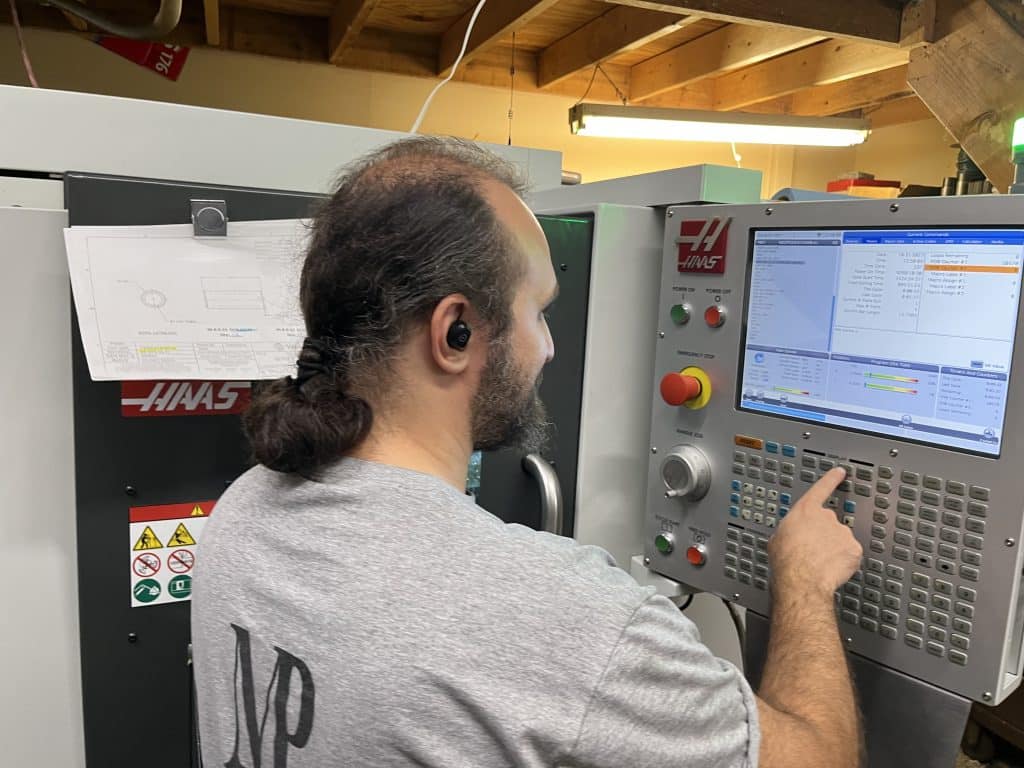

CNC machining is one of the most modern types of manufacturing. It’s known for its precision, reliability, and versatility. The machine’s ability to ‘repeat’ itself is also appealing because what it does well once, it will do well again. CNC machining works using computer-controlled machine tools to shape a material into a specific design.

Many factors are considered which influence the cost. These include:

- Complexity: The complexity of the piece factors into the cost.

- Material: The type of material needed for the part greatly influences the price because each material has a different cost. The market price is also considered so this amount can fluctuate.

- Time: How long does it take to make your piece? (This ties into the complexity as well)

- Prep Efforts: As the saying goes, time is money. When our team is busy with setting up machines for your piece, that is time spent and hours earned.

- Tool Wear: Did we go through multiples of our own tools to make your piece? All of that is factored in as well.

Maintenance: Our machines require maintenance just like a car or home. How much wear was put on our items to make yours?

Setup and Preparation: A Major Cost Driver

Unfortunately, there isn’t a magic CNC button that we have pre-programmed to make your specialty piece. There is significant time and labor involved in getting a machine to make your part.Just as you put great care into designing what you need made we put great care into making it. Our team inputs the part’s design, configures the tools, programs the machine, and makes sure all of the materials are in place before beginning the process of cutting your design.

For single-piece productions these setup costs are absorbed entirely by that one item which makes it inherently more expensive. In contrast, multiple piece runs, the setup cost is divided evenly across all of your items which reduces the cost per unit.

Material and Machining Costs

The choice of material can impact the cost as it pertains to single versus multiple items. Materials vary in price with some metals and polymers being more expensive than others.

Single pieces end up being more expensive because you’re bringing in one unique material instead of buying in bulk for multiple components. Think of it like your local Costco. You buy in bulk but ultimately save because you got more bang for your buck

The Impact of Tool Wear and Maintenance

We know what you’re thinking. “How can manufacturing one piece be more expensive on your tool wear and maintenance than multiple parts?” Again, it has to do with the great divide. We know how long it takes our personal tools to wear out or need maintenance, so for short runs or single pieces, that cost is absorbed by that one piece instead of being spread over multiple parts.

Quality Assurance Costs

Our machines are amazing, but we don’t trust them to man the helm and call it a day. Each piece has strict quality assurance in place and we have to thoroughly inspect all pieces before handing them over. The QA process of one piece takes time but over multiple pieces the QA process is streamlined.. That reduces the overall cost of QA measures.

Customization and Complexity Considerations

We work in the business of attention to detail so when it comes to our customization and design efforts, the cost goes up. Complex designs require more programming time, precision tools, and potentially longer machining times. These all increase costs. So when you opt for just one piece, the cost is higher than orders of multiples.

A good example of this would be when a simple part with all features parallel or perpendicular to each other can be machined with current tools on hand. The further a part deviates from this basic formula, the more complicated it becomes to make. It can even get to a point where a fixture is required.

A fixture is when we have to machine a piece to make a piece. Having to make a piece adds to the cost yet again, but when machining multiple pieces, that fixture cost is spread out.

Economies of Scale Explained

The concept of economies of scale play an important role in pricing in our industry. As order size increases, the cost per unit decreases because we are able to spread the costs around. The cost is spread over the setup, materials, and the ability to optimize the process in making your pieces.

Professionals in the manufacturing industry leverage economies of scale to offer competitive pricing and incentives for larger orders. It should be a major consideration for clients who are looking for CNC machining services.

Advice for Clients

We know that balancing cost, quantity, and quality requires strategic planning on the client’s part. Our best professional advice is to understand the significant cost drivers we outlined above. You’ll want to maximize manufacturability. At MP Manufacturing, we encourage you to consider your needs before deciding on one piece versus multiple.

If cost effectiveness is one of your top priorities, think of your design and the materials before making any decisions.

Looking Ahead: Trends and Cost Optimization

The future of CNC machining leans on increased automation, advanced materials, and more sophisticated technology which will all reduce costs and improve efficiency. For single-piece productions, the good news is that advancements in manufacturing are promising for cost optimization. Though, we do not see it trending to become less expensive than ordering multiples.

Understanding Pricing Is Important

Understanding the ‘why’ behind CNC machining costs, especially as it relates to one-piece manufacturing versus multiple pieces is invaluable for the relationship between clients and manufacturers. It allows for more informed decision making which ensures that projects are not only cost-effective but also top quality.

By respecting the factors that drive costs, from set up and programming to materials and economies of scale, clients can navigate their purchasing process with confidence.

Still have questions? We are more than happy to help. Call us today to talk about your project and we’ll go over it with you.