Milling machines are pivotal in manufacturing, enabling the creation of a diverse array of components with high precision. In this post, we delve into the essence of milling machines, exploring their history, functionality, and the different types available. We’re here to give you the full scoop on milling machines and the many roles they play in different industries. We want this to be your go-to guide for understanding how these machines bring ideas to life!

What is a Milling Machine?

A milling machine is a specialized tool designed to shape solid materials such as metal and plastic. It is a fundamental device in manufacturing that has evolved to meet the varied needs of different industries over the years.

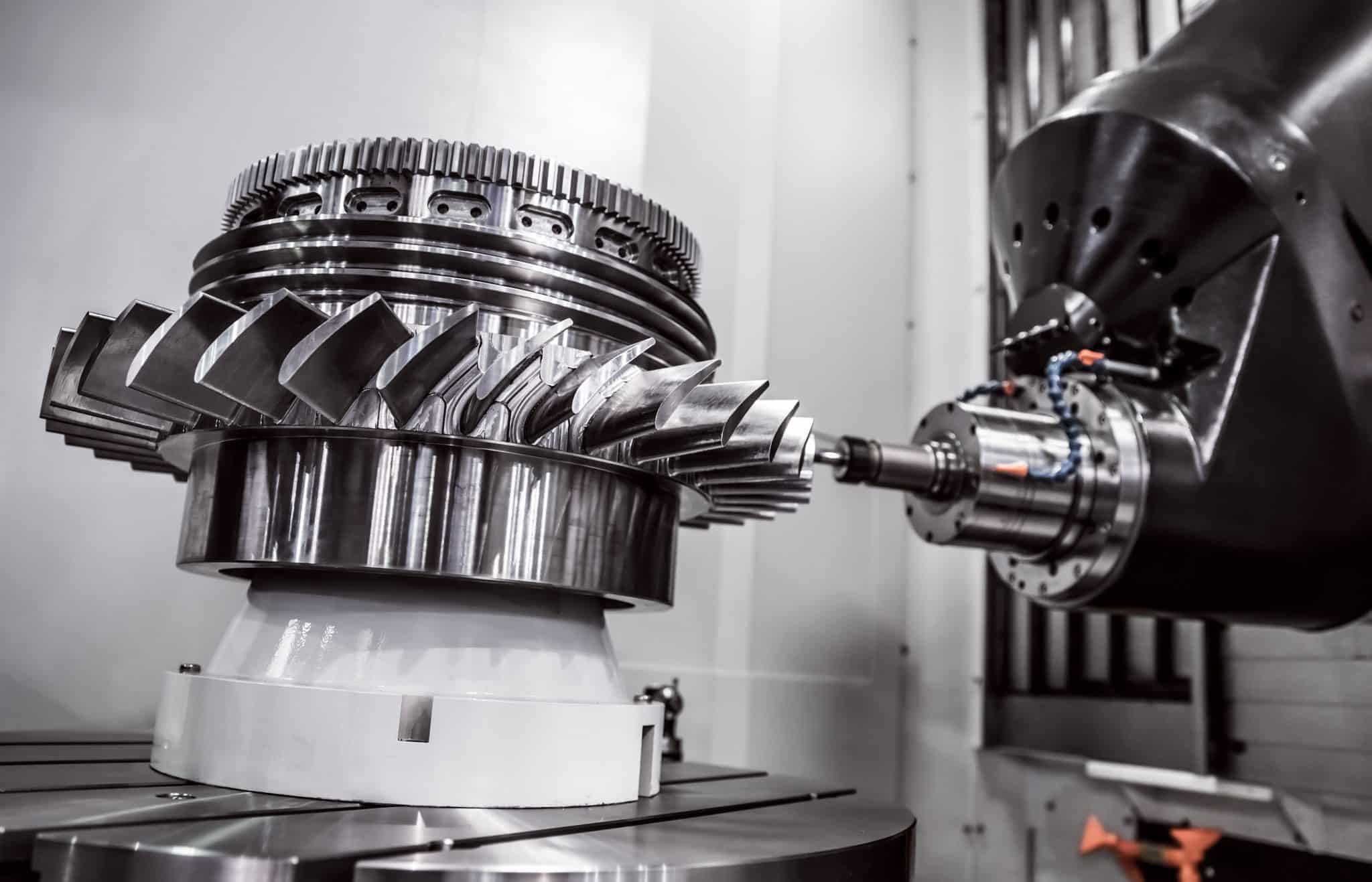

Milling machines operate by utilizing cutting tools to remove material from a workpiece. The advent of Computer Numerical Control (CNC) has greatly improved the machine’s precision and capabilities. This has allowed the production of detailed manufactured goods with high accuracy, with accuracy down to the thousandths of an inch.

These machines operate by holding the parts in place. The cutting tools then move to shape the material, often going perpendicular and parallel to the spindle axis. The operator’s expertise is crucial, ensuring the appropriate configuration of the machine and overseeing the accuracy of the milling operations.

How Does a Milling Machine Work?

Milling machines carry out their functions by employing high-speed milling cutters to shape materials. Machinists typically attach the workpiece to the machine. They then move the machine tools or milling cutters to make cuts and shapes, removing material as they go. Machinists operate these machines, adjusting the settings and monitoring the operations to ensure accuracy and precision.

The efficiency of milling machines depends on several factors. These include the type of operations, the milling cutters used, and the application of correct speeds and feeds. Proper operation is crucial to maintain the quality of the final products. Thus, the operator plays a pivotal role.

Different Types of Milling Machines

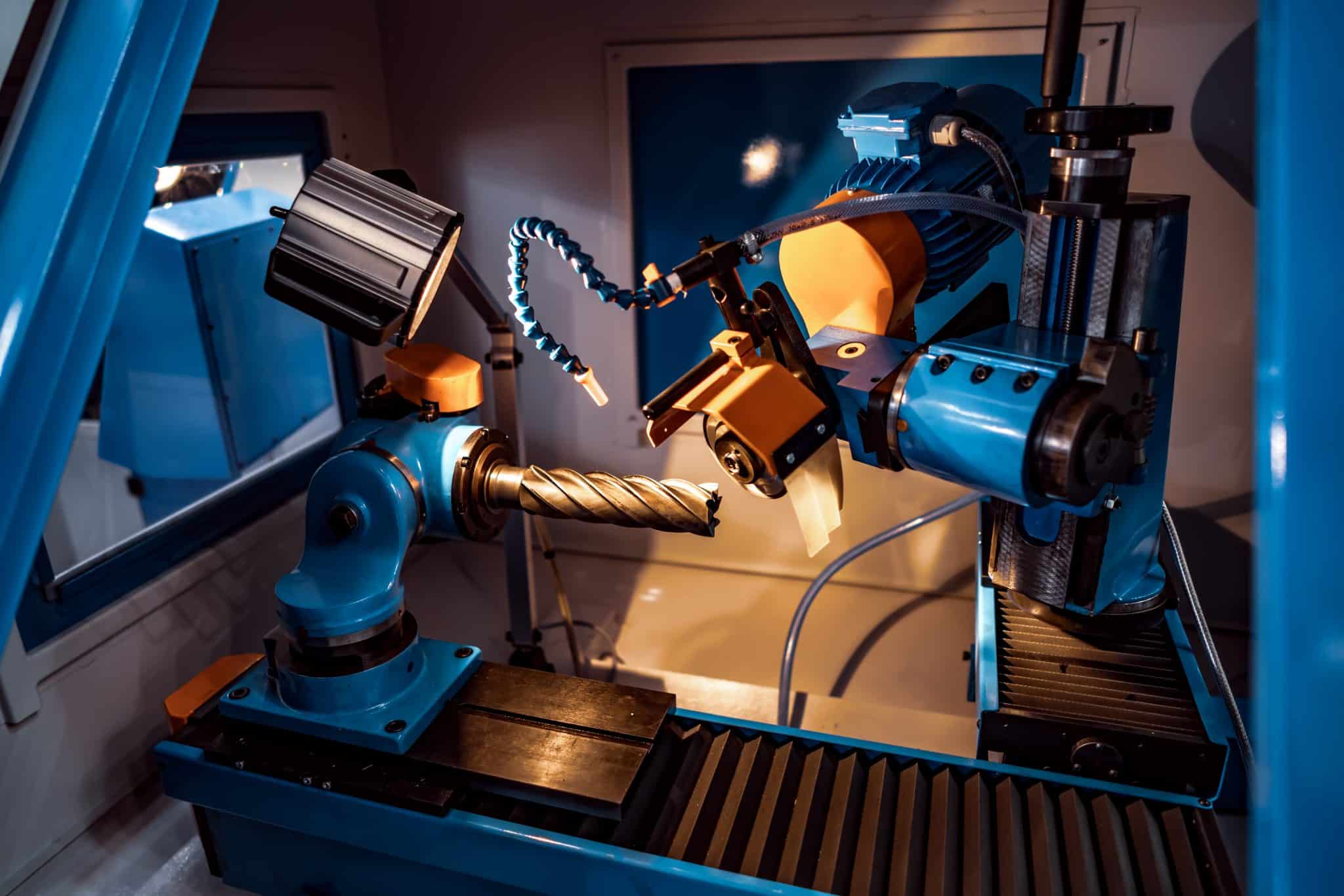

There are various types of milling machines, each with its distinctive capabilities and applications. These machines can be broadly classified into two types: manual milling and CNC machines. Manual milling machines were once the only types of machines available.

However, with the rise of CNC machines during the 20th century, manual mills are now much less common. CNC Machines utilize computer programs and automatic tool changers. This significantly increases the speed at which machinists can make parts and their overall accuracy.

You can also classify these machines based on their orientation. Vertical milling machines, also known as vertical machining centers, feature a cutting tool mounted on a spindle located above the part. The tool moves along the z-axis while the part moves along the x- and y-axis. This type of machine is suitable for detailed work.

In horizontal milling machines, also known as horizontal machining centers, the machine cuts the parts from the sides. These machines suit tasks involving heavy cutting and are common in horizontal machining centers. These machines include rotary tables. This feature enables the mounting of workpieces at various angles to create diverse shapes and sizes.

There are specialized types like CNC lathe machines, bed mills, and turret mills that allow machinists to do many different tasks. This variety ensures industries can find the right machine for their specific needs.

What Can You Make on a Milling Machine?

Milling machines can make a wide range of items, from car parts to intricate pieces of jewelry. Many industries utilize them, demonstrating their importance and flexibility in manufacturing. Basically, milling machines can make almost anything, but we don’t recommend ordering a single piece in favor of multiple pieces. It can become very expensive.

Using vertical and horizontal milling machines allows the production of components of various complexities and sizes. This meets the specific needs and preferences of different sectors.

Different cutting tools and adjustable speeds let milling machines create a wide range of items with high precision. Whether creating large structural components or small detailed pieces, milling machines are essential in any machine shop.

Unveiling the Possibilities with MP Manufacturing

At MP Manufacturing & Design, we provide a range of milling services. We use advanced CNC milling machines and skilled operators to ensure top quality and precision in our products. Whether you need components crafted with horizontal or vertical milling machines, our team can efficiently and accurately meet your needs.

We invite those seeking to understand more about milling machines and the services we offer to reach out. Our commitment is to deliver excellence in every component we craft, ensuring satisfaction and reliability. Explore the limitless possibilities and custom solutions we offer in milling. We’re here to help bring your projects to life with our CNC machining services.